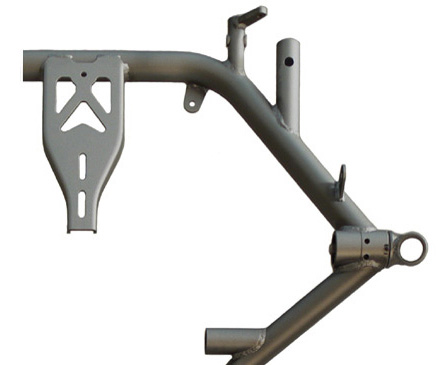

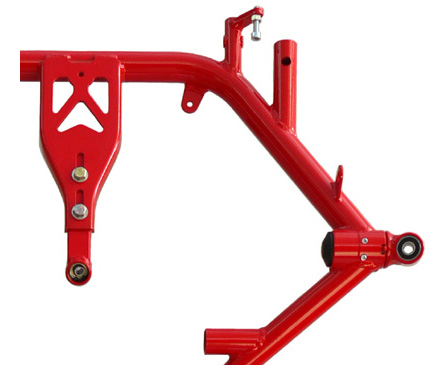

Powder coating

Powder coating is the process of coating a surface with a powder material applied by using electrostatic attraction. The applied powder is placed in an furnace and baked to an extremely hard and durable finish, very resistant to scratches, cracking, peeling and rust.

- Liquid finishing requires the use of solvents, and these solvents necessitate venting, filtering

and solvent recovery systems to control the emission of volatile organic compounds (VOC ).

Powder coating contains no solvents, therefore is a virtually pollution-free process,

exceeding all EPA standards making the powder coating process a safer and cleaner finishing alternative.

- Powder coating is more resistant to scratching, chipping, cracking, fading and wearing than any other finishing system.

- Powder coating overspray can be recycled and thus it is possible to achieve nearly 100% use of the coating.

- Powder coating can produce much thicker(40-200 µ) coatings than conventional liquid coatings.

- Powder coating is more flexible than conventional liquid coatings.

- Red / Black / Blue / Gray